In the near future, I want to address the different ways in which embroidered pillowcases are made.

Old hand-woven linen is best for embroidering pillowcases because it is not susceptible to creasing. Now I have been looking for an alternative for the embroiderers in countries where one cannot fall back on “household linen”. At the weaving mill Übelhör I found what I was looking for with durable pressed natural coloured linen.

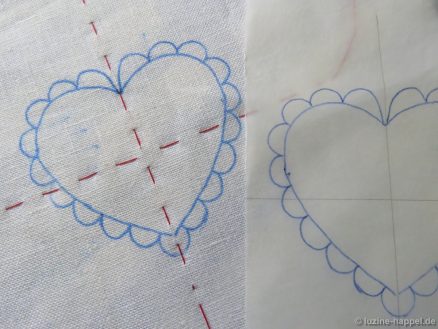

My preferred method of transferring patterns onto the linen is ironing them on with a DEKA iron-on transfer pen. However, it requires heat. The durable pressed linen, however, cannot withstand great heat. So I looked for other transfer solutions.

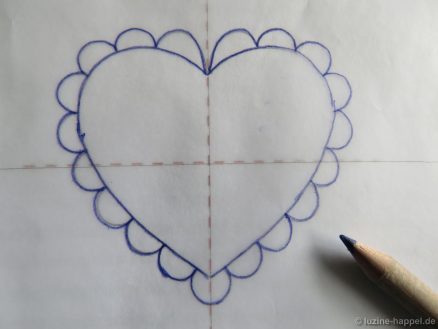

During my exhibition in September there was enough opportunity to exchange ideas about the different transfer methods used by the embroiderers. I’ll test some of them over time. Here is my experiment with a non-permanent pen from Staedtler. In contrast to the FriXion rollerball pen from Pilot, the colour can be completely washed out and does not reappear later.

Caution! I have just received a call from an embroiderer who has worked with the pen several times. She reports that the composition of the ink has been changed and the colour of the newer pens can no longer be washed out. So please check on a small test piece before embroidering whether the colour of your pen can be washed out or not.

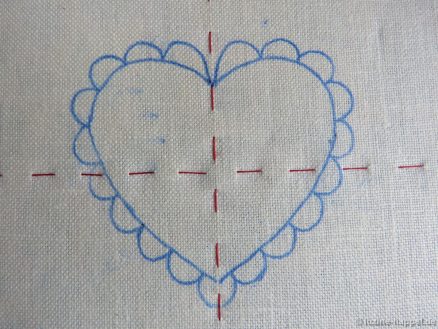

With the help of a light pad, the pattern was transferred to the linen. The natural tone of the linen is swallowing light much more than white linen, and will not allow the design lines to show through without bright lightning.

The constant up and down of the pen point crossing the threads made my lines a little bit wobbly. This I found it disturbing.

The lines turned out fine and clear, the colour is strong and lasts until the end. The pen is available in many other colours – I just happened to have a green one on hand – and also in different widths. “F” should be the most suitable for the design transfer.

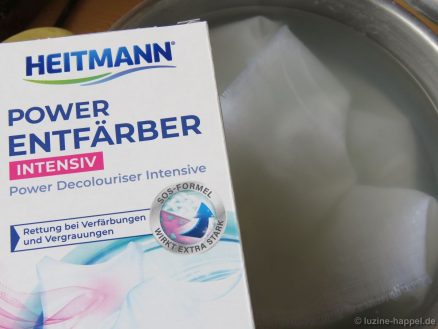

After embroidering, I put the motif in lukewarm water, and the colour immediately dissolved.

After a short time, the soap suds was coloured green.

Only a very short rubbing was necessary to wash the last remains of the ink from the linen.

The result was a clean fabric from which the outlines could be completely washed out in a very short time. If the wobbles weren’t created while tracing, this would be a perfect way to transfer designs.