I’m currently testing old, handwoven linen for its suitability for Schwalm whitework.

Handwoven linen is the ideal base fabric for Schwalm whitework. On these traditional fabrics, the embroidery develops a more three-dimensional effect than on industrially woven linen, as demonstrated by comparing the same pattern on the two substrates.

Even if the photos are not very good and clear, you can still see the difference in the unfolding of the embroidery between the industrial

and the handcrafted fabric

However, there are huge differences in the quality of handwoven linen. Many of the fabrics still found today are completely unsuitable.

Therefore, it’s advisable to test the linen before starting a larger project. If the initial tests are positive, you should examine its further properties with a small sample embroidery.

For example, you can pay attention to the following points:

1. General appearance – width; original condition or already washed?; frequency of thickening and fabric defects

2. Appearance of the fabric threads

3. Stains

4. Feel test

5. Evenness of the fabric

4. Thread withdrawing

6. Needle glide

The linen is in the original condition of the bale it was sewn into after production. It has smooth selvedges and shows the stitches used to sew the bale together in two places. After unpicking the stitches, larger holes remain visible approximately 2.5 cm deep toward the center of the fabric – but these are only small spots on the overall large piece of fabric.

Approximately 100 cm had to be trimmed off at the beginning and end of the bale because the linen was too distorted there.

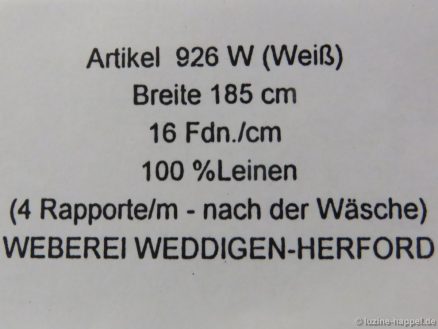

The linen is 70 cm wide – a typical width for handwoven linen.

It feels firm, but not too stiff. I would describe the handle as medium-firm.

The linen shows heavy dirt on the fold and (mostly lighter) stains over the entire surface. This is also common for linen that has been stored for many decades.

After a quick wash, all of these stains disappeared.

The following photos are highly magnified, making the aforementioned stains appear worse than they actually are.

The weave is very dense, and the threads used vary in thickness. I count 15 to 18 warp threads and 17 to 20 weft threads per centimeter.

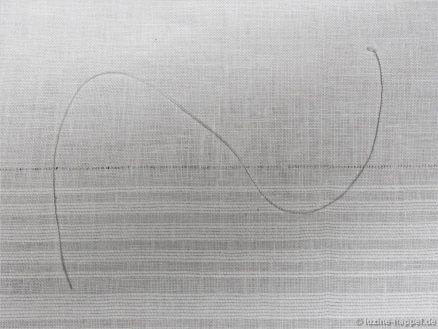

The threads are usually clearly separated from each other – a sign that they can be withdrawn easily.

But there are also areas with matting.

Every now and then (perhaps once per meter) you will find thread thickenings

and also weaving errors.

The warp thread was relatively easy to pull out without breaking. When pulling out the weft threads, they usually broke after about 3 to 5 centimeters.

To test the linen during embroidery, a small motif (18 cm x 11.5 cm) is ironed on and embroidered.

Because the linen is so tightly woven, the needle can’t glide through the fabric effortlessly. But after a few stitches, you’ll get used to it. Embroidery on handwoven linen is usually a bit more strenuous than on industrially produced linen.

Thread withdrawing in the motif areas worked well. However, I had to use a magnifying glass.

The Limet thread grid appears relatively uniform despite the different fabric thread thicknesses.

One can embroider many beautiful filling patterns into the comparatively small heart area of 4 cm width.

The density of the linen allows for precise surface embroidery.

The small embroidery looks great on the linen.

All stains have completely disappeared. The weaving flaw is unnoticeable, and the thickened threads don’t detract from the overall appearance. A somewhat irregular texture is typical of handwoven linen and contributes to the fabric’s appeal.

See also:

Selling Handwoven Linen (1)

Testing Fabric Suitability for Schwalm Whitework

Linen: Embroidery Fabric from Flax Fibers

Fault in the Linen – what to do? (1)